Installing Cylinder Heads

One last picture of the bare engine block, nice and clean and ready for the heads to go back on. Notice that the head gasket on the passenger's side has been placed on the block surface. The rubber inserts at the two lower corners had not yet been installed; they were put on shortly after the picture was taken.

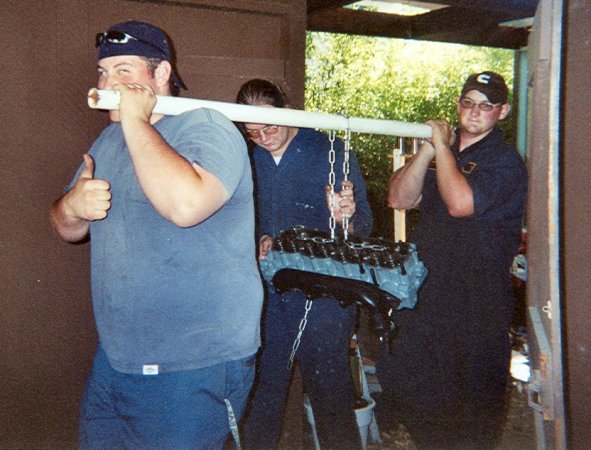

Trevor and Seth carrying the driver's side cylinder head out to the truck from the side yard where they were painted, utilizing the 10 foot pole again. I'm in the middle keeping the head stable. You can see three head studs sticking partially out of the bolt holes in the head on the right side. There are two more up above that aren't visible in this picture. With the head on the block, these will be in back, and I was concerned with the possibility of not being able to slip the studs into the holes with the head installed, due to clearance problems with the firewall and various engine compartment components. So, I used rubber bands to hold the studs up high enough in the holes that they didn't penetrate past the head mating surface. With the head on the block, the first thing to do is thread these five studs into the corresponding holes in the block, then slip the other ones in.

Carefully lowering the passenger's side head onto the engine block. Here also, I put the five rear-most studs into their holes and held them up with rubber bands (you can now see all five of them). The technique of using rubber bands on the rearmost studs came from Mel Agne's Head Gasket/Turbo Install article on TheDieselStop.com and worked flawlessly.

Similar to the passenger's side, I'm carefully guiding the driver's side head into position on the block as both Seth and Trevor lower (and raise) the bar as needed. This is certainly more crude than using an engine hoist, but it worked quite well. That said, while two people were sufficient to remove the heads, I wouldn't even consider using this method to install cylinder heads on a 6.9l with fewer than three people. The finess involved in setting the head on the block without damaging the head, block, or gasket, really requires two people holding the over 100 lbs of weight with a third maneuvering the head as needed.

Removing external parts and accessories

Heads, gaskets, and the block after head removal

Removing timing gear cover and camshaft

Cleaning the ins and outs of the engine

Final engine block cleaning with compresed air

Assembling and testing the oil cooler

First steps of modifications for the turbocharger

Comparing the stock head bolts to ARP studs (lengthy!)

Installing the cylinder heads

Installing the intake manifold and injector pump

Assembling and installing the turbocharger